PCBA Coating: The Ultimate Solution for Circuit Board Assembly Protection

PCBA Coating Printed circuit board assembly coating plays a crucial role in protecting the delicate electronic components that are present on circuit boards. It is essential to ensure the reliability and longevity of these assemblies, and PCBA coating provides an effective solution to achieve this goal.

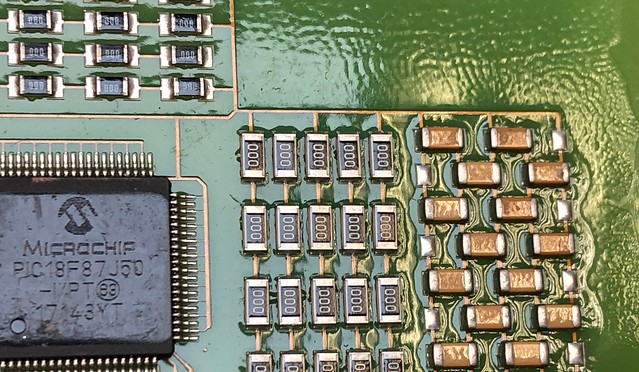

PCB Assembly Level Conformal Coating is a widely used method of protecting printed circuit boards from environmental factors such as moisture, dust, chemic

als, and temperature variations. This coating creates a protective barrier over the PCB surface, shielding it from potential damages. With advancements in technology, various types of coatings are available today to cater to different PCB applications.

One of the primary advantages of using PCBA coatin PCBA Coating g is its ability to provide insulation against electrical interference. It prevents leakage currents by creating a dielectric layer that isolates adjacent conductors on the PCB assembly. This property enhances the overall performance and ensures uninterrupted operation under di PCB Assembly verse conditions.

The manufacturing process involves applying a thin layer of conformal coating materi PCB Assembly al onto the PCB surface either through spraying or dipping methods. Subsequently, curing is carried out either at room temperature or with specific heating techniques depending upon the type of material chosen for coating purposes.

Choosing the right type o PCBA Coating f PCBA coating for your project depends on several factors such as application environment, operating temperatures, thickness requirements, and desired protection level. Various materials including acrylics, urethanes, epoxies & silicones offer different characteristics like chemical resistance flexibility & waterproofing capabilities.

To select Printed circuit board assembly coating an appropriate product among multiple options available in market,you should carefully evaluate its compatibility with other materials used in your specific application as well.It’s always recommended to consult experienced professionals who can guide you effectively based on their knowledge & expertise.Electronics manufacturers can also benefit from partnering with reliable suppliers who d PCBA Coating eliver quality products meeting industry standards helping them save time,money & effort while ensuring better results.

In conclusion,the significance posed by printed circuit board assembly coa Board level conformal coating ting cannot be understated.It safeguards the electronics from potential harm due to environmental factors,enhances performance and prolongs lifespan of PCB assemblies.It is essential that manufact Circuit board assembly protection urers pay careful attention to selecting the right type of PCBA coating based on their requirements in order to achieve optimal results and ensure ultimate customer satisfaction.