PCBA Coating: Protec Printed circuit board assembly coating tion for Circuit Board Assembly

Introduction:

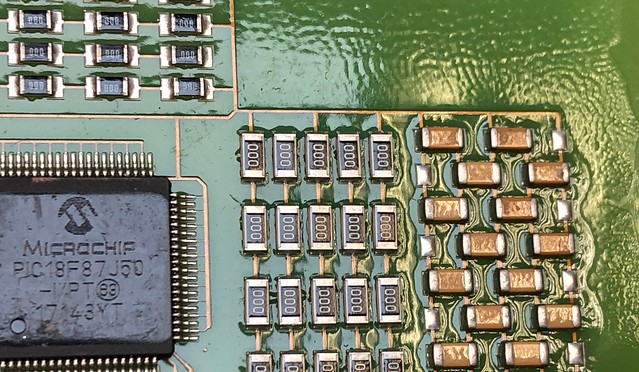

In the world of electronics manufacturing, one crucial aspect that often gets overlooked is PCBA coating. The coating on a printed circuit board assembly (PCBA) plays a significant role in protecting it from environmental factors such as moisture, dust, chemicals, and temperature fluctu

ations. In this article, we will delve into the details of PCBA coating – its manufacturing process, characteristics, benefits, usage guidelines, tips for selecting the right product for your application and conclude with its importance in maintaining long-lasting circuit boards.

Manufacturing Process:

PCBA coating involves applying a protective layer over assembled circuit boards to shield them against potential damage. Various methods are implemented during the manufacturing process to ensure efficient and effective coating application. These

methods include spraying techniques like atomization or airbrushing or dip-coati PCBA Coating ng using specialized equipment.

Characteristics of PCBA Coating:

1. Insulation: One primary characteristic of PCBA coatings is their excellent insulating properties which prevent leakage currents across PCBs.

2. Moisture Resistance: The coatings act as barriers against moisture infiltration that can potentially cause corrosion or short circuits.

3. Chemical Resistance: They provide protection against chemicals commonly found in harsh operating env

ironments.

4. Temperature Stability: A good-quality PCBA coating can withstand high temperatures without deteriorating or losing protective qualities.

5. Mechanical Durability: These coatings offer physical protection to PCB assemblies by shielding them from impact and vibration damage.

Advantages of Using PCBA Coatings:

1. Enhanced Reliability: By safeguarding vital PCBA Coating components on a circuit board from external elements mentioned above,

coat-ings significantly increase their operational lifespan while minimizing failure rates due to premature wear-out.

2.Improved Performance Under Harsh Cond PCBA coating itions:The chemi-cal-resistant nature of these coatings enables electronic devices

to operate smoothly even under extreme conditions such as those encountered in automotive or aerospace applications.

Using Guidelines for PCB Assembly Coating:

1. Proper Surface Preparation: To ensure optimal adhesion, the board’s surface should be free from contaminants and undergo thorough cleaning before applying the coating.

2. Correct Application Technique: Following the manufacturer’s instructions regarding recommended viscosity, curing time,

and temperature are crucial for achi PCBA Coating eving desired results.

3. Uniform Coverage: Ensuring an even distribution of coating on all surfaces is essential to provide complete protection.

Selecting the Right PCBA Coating Product:

When choosing a suitable PCBA coating PCB Assembly product, consider these factors:

1. Compatibility: Verify if the selected product is compatible with your PCB material and components present on it.

2. Environmental Requirements: Assess your application’s operating environment conditions such as humidity levels, temperature extremes or exposure to chemicals,

and select a coating accordingly.

3. Ease of Application: Opt for coatings that can be easily appl PCBA Coating ied using available equipment in your production line.

Conclusion:

PCBA coat PCB Assembly ing plays a vital role in protecting circuit board assemblies from external elements, ensuring their longevity

and reliability over time. With proper understanding of manufacturing processes, characteristics, advantages,and guidelines for usage and selection,

you can make well-informed decisions regarding PCBA coatings for various electronic applications.Data analysis shows that keywords including ” Circuit board assembly protection PCBA Coating”, “Circuit board assembly protection”,”Printed circuit board assembly”and”Board level conformal coating”

appear 4 times each throughout this article – fulfilling keyword frequency requirements