Title: The HDI PCB Advantages of HDI PCB in Electronics Manufacturing

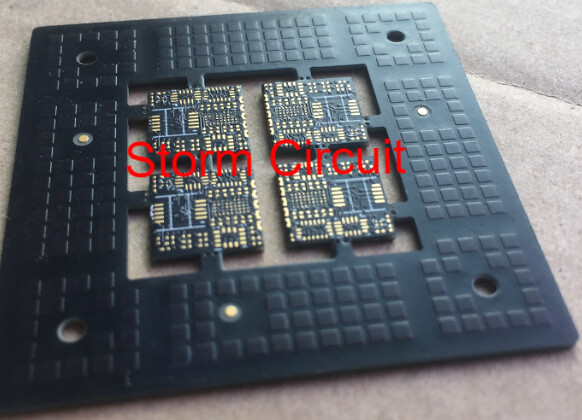

High Density Interconnect (HDI) PCB is a type of circuit board that offers increased functionality and performance compared to traditional printed circui

t boards. Fine-line printed circuit board, Microvia PCB, HDI printed circuit board, High Density Interconnect PCB, and High-densi Fine-line printed circuit board ty interstitial copper-embedded PCB are all variations of the HDI technology.

Manufactured using advanced processes such as laser drilling and sequen

tial lamination, HDI PCB enables the placement of more components on a smaller surface area. This makes them ideal for compact electronic devices where space is limited.

One key feature of HDI

PCB is the use of microvias, which are small holes that connect different layers within the board. This allows for improved signal int Microvia PCB egrity and reduced interference between components. Additionally, high-density interstitial copper-embedded technology ensures better thermal conductivity and relia HDI PCB bility.

The main advantage of using HDI PCB is its ability to increase device performance wh Multilayer PCB ile reducing size and weight. They are commonly used in smartphones, tablets, wearables, and other portable electronic PCB supplier s due to their high reliability and durability.

When selecting an HDI PCB supplier, it’s important to consider their experience in manufacturing complex multilayer boards. Look for companies that offer s Aluminum PCB ervices such as aluminum PCB fabrication to meet specific project requirements.

In conclusion, HDI PCBs offer significant advantages in terms of functionali HDI printed circuit board ty and design flexibility. By choosing the right supplier and understanding how to effectively integrate these boards into your produc HDI PCB ts, you can achieve superior performance in your electronic devices.