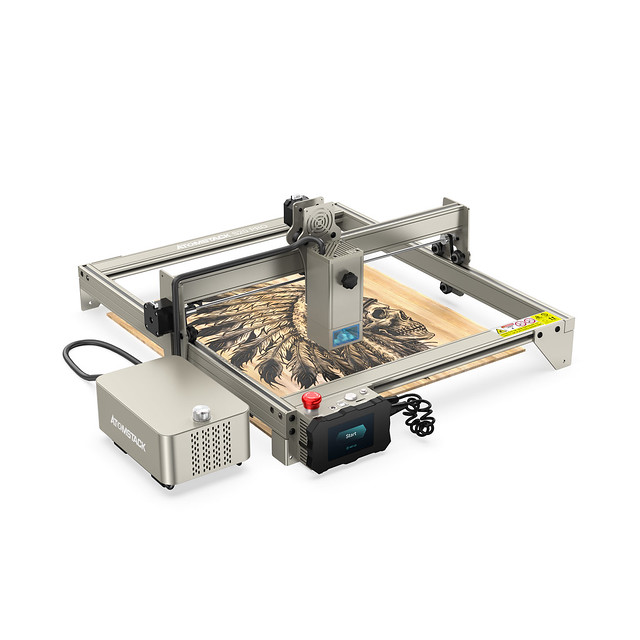

Diode Laser Machine: A Cutting-Edge Technology Revolutionizing Medical and Industrial Applications

Introduction:

In recent years, there has been a

significant breakthrough in the field of laser technology with the introduction of diode laser machines. These state-of-the-art devices have gained immense popularity due to their high-power capabilities and versatility across various industries. This article explores the fractional co2 laser machine supplier manufacturing process, features, advantages, usage methods, tips on selecting the right product, and concludes with a reflection on the impact these machines have had on our lives.

Manufacturing Process:

The diode laser machine is manufactured using advanced semiconductor technology. It consists of multiple layers of semiconductors that are doped differently to create an efficient light-emitting device. The entire production process i

nvolves precise control over material composition and layer thickness to enhance performance and ensure reliability.

Features:

One notable feature is the integration of a high- Near infrared light emitter power LED module within the diode laser machine. This enables it to generate intense beams of near infrared light for highly effective treatments. Additionally, opto-electronic component systems are incorporated into these machines to ensure reliable operation even under challenging conditions. These components provide stability in output power while minimizing aberrations typically associated with traditional lasers.

Advantages:

The usage of diode laser machines offers numerous advantages compared to other types of lase diode laser machine rs available in the market today:

1. Versatility: Diode lasers can be used in diverse fields such as medicine, aesthetics, research laboratories, telecommunications, material processing industries (including cutting & welding), and more.

2. diode laser machine Precision: By utilizing focused energy delivery through adjustable spot sizes or fiber optics delivery system options.

3. Efficiency: Diodes convert electrical energy directly into light energy with minimal heat dissipation ensuring maximum effici diode laser machine ency during operation.

4.Cost-effective Solution: With extended operational lifetimes and lower maintenance requirements than conventional solid-state lasers; they prove beneficial economically.

Usage Methods:

1.Medical Field– In dermatology clinics, diode laser machines have revolutionized treatments High-power LED module for hair removal, skin rejuvenation/stretch marks reduction. This technology is also applied in ophthalmology for retinal surgery and as photodynamic therapy.

2.Industrial Applications – Diode lasers are widely used due to their superior performance in material processing tasks such as weldi

ng, cutting metals/plastics, soldering electronic components/fiber optics.

How to Choose the Right Product:

Selecting the right diode laser machine involves considering several essential factors:

1. Power output requirements: Identify your specific application needs according to power demands.

2. Wavelength selection: Depending on diode laser machine your target material absorption properties.

3.Reliable supplier– Select a reputable fractional co2 laser machine supplier known for delivering high-quality products with reliable after-sales service/support.

Conclusion:

The advent of diode laser machines has undeniably transformed various industries by offering enhanced precision and efficiency at an affordable cost. With their versa fractional co2 laser machine supplier tile applications in both medicine and industrial sectors, these devices have opened up new possibilities while revolutionizing traditional treatment methods and manufact Opto-electronic component system uring processes. By understanding the manufacturing process, key features, advantages, usage methods – combined with careful product selection from trustworthy suppliers – users can harness the full potential of diode laser machines efficiently and effectively.